High Quality Control for Difficult-to-Inspect Products and Small Batch Sizes

Our approach to automated visual inspection goes beyond traditional visual inspection solutions. Based on our holistic system, both software and hardware are individually tailored to customer requirements.

Camera Based Visual Inspection

Parenteral drug products are required to be 100% visually inspected. As each product and its packaging define their specific inspection task, standardized inspection setups may lead to a high level of false rejects and underperforming inspection results. In contrast, a highly customized solution provides the opportunity to take the inspection to the next level.

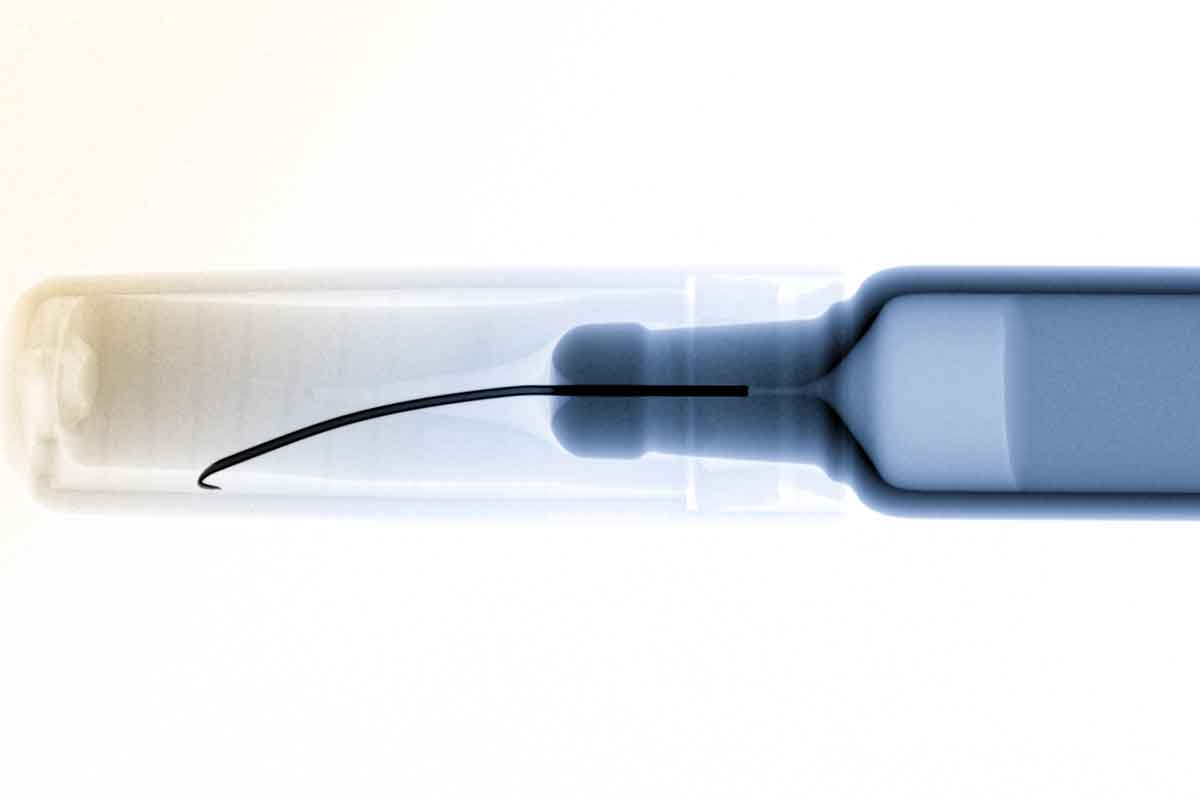

X-ray Based Visual Inspection

Our X-ray inspection allows the non-destructive inspection of pre-filled syringe needles and needle covers direct in the filling line with minimal space requirements.

Image Processing

We have a large toolbox of state-of-the-art image processing algorithms which are selected and combined as required for the individual inspection task. Furthermore, each inspection setup, which consists of hard- and software, is tailored to the process and the individual inspection task for the best possible outcome. A detailed investigation of the defect catalogue and pre-engineering in our vision lab define the algorithms and detection rates to be expected at an early stage of the project.

Looking for more information about our automated visual inspection capabilities?

Get information directly from our experts.