Near Infrared Spectroscopy (NIRS) is an economic and cost effective method of analysis. It is used for the identification or quantity analysis of lyophilizates, powders, granules, etc. The NIRS covers a very wide range of applications in pharmaceutical, food and beverage industry. NIR measurements can be performed off-line, or at-line, or in-line for process analytical technology (PAT).

Why NIR inspection is important

Residual moisture in lyophilizates is a critical quality attribute of a drug and has an impact on its long-term stability. Therefore, the moisture concentration needs to be verified. The Karl Fischer Titration is a widely used and established method for that application. However, the method requires the sample to be destroyed in order to test it and therefore does not allow a 100% inspection. Other lyo defects such as meltbacks or shrunken cakes may be detected with other methods such as visual inspection, which is limited to the inspection of the lyo surface.

Working principle of Near Infrared Spectroscopy (NIRS)

NIR inspection is a process analytical technology which supports the assessment and control of the pharmaceutical freeze-drying manufacturing process through the analysis of the spectra of the freeze-dried cakes.

In the NIR spectral range in particular, overtones and vibrational combinations of OH-, NH- and CH- fundamental vibrations can be observed. The intense spectral features of most organic substances can be measured in the spectral range between 1100 nm and 2500 nm (10.000 cm-1 and 4.000 cm-1), consequently this area is widely used.

- The principal set up in which to achieve the NIR spectra in reflection mode

- The illumination using tungsten halogen lamp which illuminates the vial from below

- Light is reflected of off and scattered by the lyophilizate within the vial and then focused via a fiber optic cable at the entrance split

- Beam hits holographic grating and is reflected on photo diode array detector

- Grating splits radiation into individual wavelengths

- Detector generates digitized output signal (spectrum) to be converted

With NIR technology, changes in the cake condition can be detected more sensitively than with an optical system. This is why NIR is the preferred inspection technology for meltback defects.

NIR inspection possibilities

The measurements are performed without data pretreatments either in diffuse reflection or in transmission. The NIR spectra contain chemical as well as physical information. A simple and direct interpretation of the spectra is inconceivable. Therefore, it is necessary to use a little more extensive chemometric algorithms for interpretation and evaluation of the spectra.

Diffuse reflection

Diffuse reflection is primarily used for the investigation of powder samples, but is also used for granulates or pastes, lyophilizates, other solids as well as gels.

The NIR radiation incident on the sample, penetrates the surface and is diffracted by the particles and reflected diffusely. The reflected radiation contains the spectral information about the sample.

Advantages

- No sample preparation is needed

- chemical and physical information is gathered

Transmission

A transmission setup is the optimum method for liquids. The samples are irradiated in a defined layer thickness. The transmitted light contains the spectral information.

Advantages

- Well defined conditions

- high signal yield

Applications

Active ingredients and auxiliary material in the solid and liquid form can be identified and quantified.

Identification of the different products

The reliable identification of different products or raw materials as well as classification of different groups is essential in the pharma and food industry.

For the production process of lyophilizates the NIR application provides a significantly higher level in quality control.

An application distinguishes the different product mixtures and raw materials on the basis of principal component analysis.

Following chemometric methods are used for identification or classification:

- Cluster analysis or Principal Component Analysis (PCA)

- Support Vector Machine Classification (SVMC)

- Linear Discriminant Analysis (LDA)

- Partial Leas Squares Discriminant Analysis (PLS-DA)

Quantification Methods

The results of NIR spectroscopy are obtained in real time. This allows fine adjustments in processes and increases the productivity. An example of this is measuring the moisture content in lyophilizates.

These spectra of lyophilizate are recorded and calibrated with the reference method Karl Fischer titration. The content of one or more components, based on calibrations, is determined from the NIR spectrum. These were recorded and stored in advance with samples of known content. The method Partial Least Squares Regression (PLS) is the basis for the quantitative analysis. The calibration shows accurate results for the moisture content in lyophilizate.

The NIR technology is an indirect method and requires an absolute comparison method. It is combined with the classic reference method.

For the quantitative evaluation the following chemometric method is used:

- Principal Leas Squares Regression (PLS)

Hierarchical Modelling (HM)

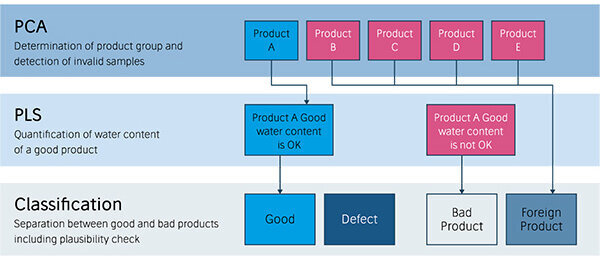

Hierarchical Modelling (HM) is a step by step analysis for different properties on a given set of information, in the case of NIR a spectrum. It is the combination of a number of assembled, multivariate models in order to get a clear result for different properties. Sometimes a single classification or a prediction model of moisture is not enough in order to fully describe a sample or the underlying process. Therefore, a model is applied, that consists of other specific models. The user will then get a result from each of the models about one property of the sample and the underlying process.

Example Hierarchical Modelling (HM) for product A

The HM Model of the process analysis consists of the following steps:

1. Identification of the product

The PCA qualitative analysis is used for the identification of different products. PCA shows the ability to discriminate between the different populations of the sample classes.

2. Moisture evaluation

The PLS quantitative analysis is used for the determination of water content in the cake. The correlation between spectral data and the corresponding water content values, using Karl Fischer method as reference analysis, of the individual components is created using PLS algorithm.

3. Cake defect classification

SVM algorithm is used for the classification of different classes, for example, the separation between good and bad classes of the cake based on defects.

Combination with other inspection technologies

A combination of various inspection technologies with NIR inspection can significantly increase process reliability. A combination with our Headspace Analysis (HSA), differential pressure or automated visual inspection solution is easily possible.

Versatile NIRS solutions

The semi-automatic laboratory system is suitable for model development. Fully automatic inline solutions can process up to 600 products per minute in production. The NIR solution can also be supplied as a single module which can be easily integrated into any production line.

Method development and validation as key to success

During the method development process, the product specific spectra are analyzed and build the basis for the chemometric model. Each model is tailor-made to the individual product allowing the highest level of sensitivity. As a reference method the Karl Fisher method is used.

Advantages of our NIR inspection solutions

- Extremely short measuring times – non-destructive

- Exact and validatable measurement values (data driven PAT)

- Environmentally friendly – no sample preparation, no chemical wastes

- Safe – no chemical reactions

- Versatile – simultaneous determination of various parameters

- Online application for process control

- Easy to use – user-friendly application

- Replaces a large number of time consuming wet-chemical analysis methods in combination with a chemometric evaluation.

- The NIR data gives the same reliability which is comparable to the reference analytic methods (e.g. Karl Fischer Titration, HPLC)

Would you like more information about the PAT possibilities with NIR spectroscopy?

We will be happy to advise you personally.