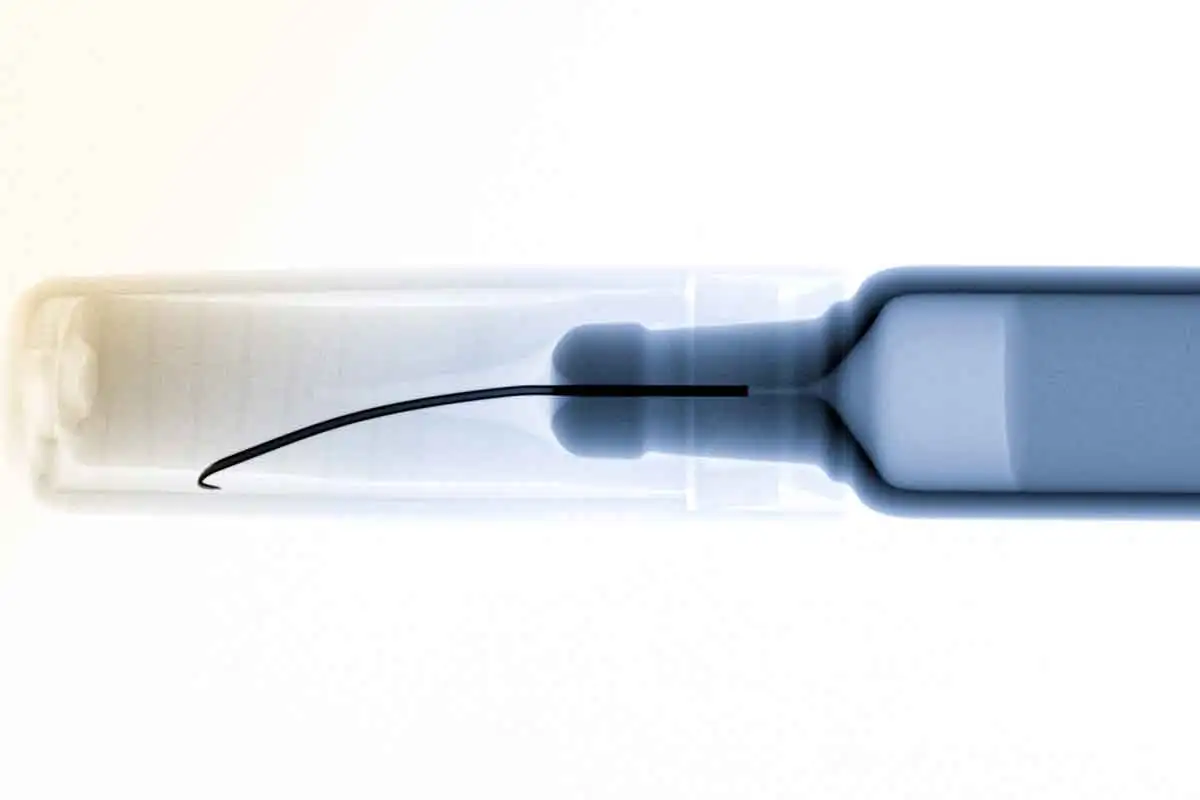

The CUBE XRS is an advanced X-ray inspection module specially developed for the inspection of syringe needles before the filling process. The module can be seamlessly integrated into B+S syringe filling lines with minimal space requirements. The syringe needle and needle cover of various formats can be reliably inspected at full production speed.

Why X-ray inspection is important

We have developed a method for the inspection of syringe needles and syringe covers using X-rays. A low-energy X-ray source combined with sophisticated image recognition and processing technology enables the detection of functional defects such as poor needle alignment of a syringe or defects in the syringe cover. By inspecting syringes before the filling process, you ensure that only flawless syringes are filled and further processed.

Working principle of X-ray inspection

While passing through the low-energy X-ray field, any samples and their potential defects, are magnified onto a fast CMOS detector array. The resulting size of the sample or defect image can be calculated due to the distance relations between X-ray source / sample and sample / detector.

The detector converts the incoming X-rays into light and transfers the picture onto the CMOS diode array. The results are immediately available and are evaluated instantaneously, allowing the processing of high production speeds.

X-ray is an imaging technology which creates 2D images that can then be inspected for defects. In X-ray imaging, not only the detector needs to fulfill certain requirements but also the X-ray source itself is required to obtain some crucial properties. These properties are defined by the field of application. In short the technology defines two types of X-ray tubes. The first one is the closed tube design producing radiation with a focus between 800µm and 1500µm and the second is the micro-focus tube design with a focus between 1µm to 5 µm. In general it is the focus diameter that defines the spatial resolution of such an imaging system or the smallest object which can be made visible in such a picture.

Highlights of the X-ray needle inspection module

- Ready to fill syringes inspection of: Needle length, needle angle, angle of needle shield and needle shield puncture

- Advanced integration: Seamless PLC and HMI integration with Bausch+Ströbel syringe lines

- Flexibility: Supports multiple format sizes in compact design for Cleanroom Class A/B integration

- Safety: Fully enclosed system with additional shielding, in compliance with regulatory approvals

Advantages of our X-ray inspection solution

- Fully automatic test procedure

- 100 % inline inspection

- Simultaneous inspection of 12 syringes

- Applicable for multiple format sizes

- Compact design

- High-resolution X-Ray images

- Performance test with reference object can be performed at pre-batch, batch, and post-batch processing

- Replaceable filament extends X-Ray source life

- Low maintenance cycle

- Low operating costs

- No increased radiation dose above 0.1 µS/h

Looking for more information about our X-ray capabilities?

We are happy to advise you personally.