Automated visual inspection of small-scale production of parenterals with WILCOs EVO CAX

In the realm of small-scale production, ensuring impeccable quality control for clinical trials, eject inspection, high-value products, and media fill inspection demands nothing less than a 100% visual inspection. However, these highly individualized use cases present numerous challenges for automated inline solutions. Therefore, we have developed the fully automated visual inspection platform EVO, designed for the inspection of high-mix/low-volume parenterals on a smallest possible footprint.

Meeting the Challenges of Visual Inspection for Small Batch Sizes Today

The trend towards personalized healthcare leads to smaller batch sizes and higher product change. Traditionally, the best inspection solution for small-scale pharmaceutical productions has been manual visual inspection (MVI), necessitating extensive personnel training. However, the irregular development cycles in clinical production pose challenges for MVI operators, as products can change significantly from batch to batch and individual production campaigns can be far apart.

Is automation possible for high-mix/low-volume products?

Absolutely! Collaborating closely with a client, WILCO has engineered a system that automates the visual inspection of small batches, setting a new standard for Automated Visual Inspection (AVI). The EVO CAX not only delivers exceptional reproducibility and consistency of results but also ensures strict adherence to stringent quality standards. With advanced capabilities designed to address the evolving demands of the pharmaceutical markets, the EVO CAX provides a reliable and fast alternative to manual inspection methods.

Human-like visual inspection: Precision and Innovation in Pharmaceutical Inspection

In the pharmaceutical industry, precision is paramount. The EVO CAX integrates the accuracy of robotic systems with an award winning human-inspired methodology for product handling. By mitigating forceful motions and embracing delicate mechanical procedures, we eliminate the necessity for rapid product spinning. This strategic approach not only safeguards product integrity but also elevates the holistic quality of inspections, setting a new standard in pharmaceutical visual inspection practices.

Small, flexible and scalable: The EVO CAX advantages

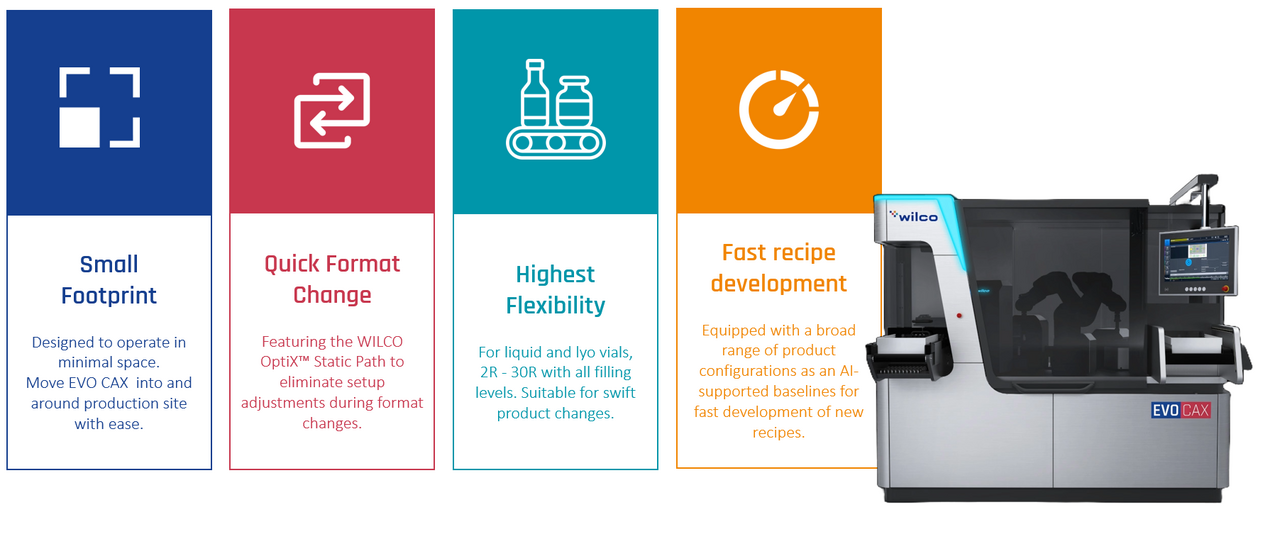

The main features of the EVO CAX are not only a very attractive design but also:

- Small Footprint: Engineered to operate within minimal space, meaning smaller than the size of two MVI stations (2.5 x 1.15 x 2.25m)

- Quick Format Change: Featuring the WILCO OptiX™ Static Path to eliminate setup adjustments during format changes

- Highest flexibility: For liquid and lyo vials, 2R-30R with all filling levels

- Fast recipe development: Equipped with a broad range of product configurations and an AI-supported baseline for fast development of new recipes.

- Scalable with EVO fleet concept: Transfer validated recipes to a production environment with only one operator being able to run up to four systems simultaneously

Get more information

Download the EVO brochure or contact us to discuss your upcoming project to automate your visual inspection tasks.

Looking for Automated Visual Inspection Solutions?

We are happy to advise you personally